Introduction to PVDC

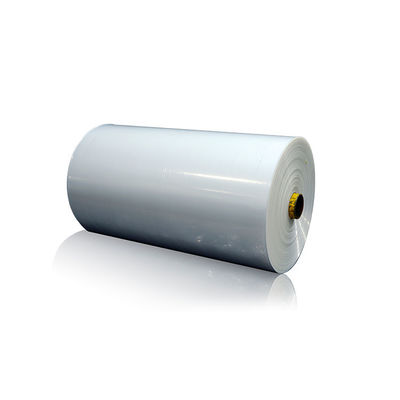

PVDC scientific name polyvinylidene chloride, softening temperature 160℃-200℃, the production of film density 1.6 ~ 1.7g/cm³.

PVDC molecular chain has high regularity, symmetrical structure and large polarity, and is easy to form hydrogen bonds.

High crystallinity, small grain size, no hydrophilic groups, excellent barrier performance.

PVDC came out in the 1930s, the first used for military supplies, military supplies moisture-proof, anti-oxidation packaging, due to excellent barrier performance, is now used in food, medicine, chemicals, electronic devices packaging.

Why choose PVDC as the barrier layer

Excellent barrier performance: PVDC has excellent oxygen resistance, gas resistance, moisture resistance, taste protection performance, is currently recognized as the best comprehensive barrier performance of plastic packaging materials.

Stable barrier performance: changes in ambient temperature and humidity have no effect on the PVDC barrier performance.

Excellent weather resistance: strong anti-aging ability.

Safe and environmental protection, FDA certification can be in contact with food.

PVDC can provide reliable quality and security for the packaged products.

Environmental protection of PVDC

In the United States, PVDC products are identified as non-toxic and safe plastic materials that can be used in food packaging and meet FDA certification.

In Germany, PVDC packaging is classified as green packaging and holds the "green dot mark".

Japan confirmed that the incineration of PVDC had no effect on the amount of dichalk produced, and a large number of PVDC products were used for packaging.

◎ Water vapor transmission detection and comparison: PVDC's water vapor barrier performance is equivalent to 7 times that of HDPE, 120 times that of EVOH and 437 times that of PA (test conditions are 38℃, 24h, 90%RH, 25μm).

◎ Oxygen permeability test comparison: the oxygen barrier performance of PVDC is equivalent to 2735 times that of HDPE and PP, and 47 times that of PA (test conditions are 20℃, 24h, 0.1MPa, 75%RH, 25μm).

◎ Air permeability detection comparison: PVDC's odor barrier performance is equivalent to 84 times that of PA and 5700 times that of HDPE (test conditions are 20℃, 24h, 0.1MPa, 75%RH, 25μm).

Conclusion: PVDC is the most stable plastic packaging material with barrier properties, which can provide reliable quality and safety guarantee for the packaged products.

PVDC Application

Packaged products: Ham sausage treated with high temperature sterilization

PVDC film Category: Sheet PVDC casing film (surface printing and inner printing process)

Packaging equipment: lashing machine

Sealing principle: high frequency current welding

The advantages of Shuanghui PVDC casing film

The physical and mechanical properties are excellent and stable, and the production rate of ham sausage is high.

Strong adaptability, can be applied to different meat recipes.

Inside printing patented technology to ensure the perfect display of product image.

Medium and low temperature series product packaging

Packaged products: products that have been sterilized twice at low temperature

PVDC film category: PVDC composite film, PVDC composite bag

Packaging equipment: stretch film vacuum packaging machine, vacuum packaging machine

Sealing principle: hot pressing sealing

PVDC Composite film/bag Typical structure:

Advantages of Shuanghui PVDC composite film/bag

Excellent and stable barrier property: effectively extend product shelf life.

Ensure product quality: maintain the original flavor of the product, improve consumer brand recognition.

Breaking the narrow restrictions of medium and low temperature meat products sales channels, achieving the normal temperature circulation of China's medium temperature meat products, and promoting the leap in the image, quality, safety and production efficiency of China's medium and low temperature meat products.

Improve food safety: Reduce legal risks associated with improper use of preservatives.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!